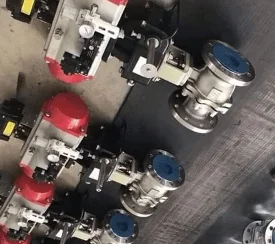

Pneumatic Actuated Ball Valve

South American Valve is the greatest pneumatic actuated ball valve supplier in Chile. A pneumatic actuated ball valve is a type of valve that uses compressed air or gas to control the opening and closing of a ball within the valve body. It is commonly used in various industrial applications where automated flow control is required. The valve consists of a hollow ball with a hole or bore through its center. When the valve is open, the bore aligns with the flow path, allowing fluid or gas to pass through. When the valve is closed, the ball rotates to a position where the bore is perpendicular to the flow path, blocking the flow.

South American Valve is the greatest pneumatic actuated ball valve supplier in Chile. The pneumatic actuator attached to the valve provides the necessary force to rotate the ball and control the flow. The actuator typically consists of a pneumatic piston, diaphragm, or motor, and various control components. It receives signals from a control system or operator and translates them into linear or rotary motion to open or close the valve. Pneumatic actuated ball valves find application in various industries, including oil and gas, chemical processing, water treatment, HVAC systems, and power generation. They are used in processes where automated flow control, precise regulation, and remote operation are desired.

Parts

- Body

- Stem

- Ball

- Actuator

- Stem

- Bonnet

Applications

- Process Control: Pneumatic actuated ball valves are widely used in process control systems for regulating the flow of fluids or gases. They are employed in industries such as oil and gas, chemical processing, water treatment, and pharmaceuticals, where accurate control of flow rates is critical for efficient operations.

- HVAC Systems: Pneumatic actuated ball valves play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They are used for controlling the flow of hot or cold water, steam, or refrigerants to maintain optimal temperature and ensure proper functioning of the HVAC equipment.

- Water and Wastewater Management: Pneumatic actuated ball valves are commonly used in water distribution systems, wastewater treatment plants, and irrigation systems. They help regulate the flow of water, control pressure, and manage the distribution of treated water or wastewater.

- Fire Protection Systems: Pneumatic actuated ball valves are employed in fire protection systems, such as fire sprinkler systems and fire hydrants. These valves enable the rapid opening or closing of water flow in case of a fire emergency, ensuring effective fire suppression.

- Fuel and Gas Handling: Pneumatic actuated ball valves are utilized in fuel handling systems, including pipelines and storage terminals. They control the flow of liquid fuels, such as gasoline, diesel, or aviation fuel, as well as natural gas and other gases used in industrial processes.

- Laboratory and Research Applications: Pneumatic actuated ball valves find applications in laboratories and research facilities where precise control of fluid flow is required. They are used in analytical instruments, bioreactors, and experimental setups to regulate the flow of chemicals, gases, or other fluids.

Benefits

- Precise and Accurate Control: Pneumatic actuated ball valves provide precise and accurate control over fluid or gas flow. The electric actuator allows for fine-tuned adjustments, enabling the valve to be positioned at specific angles for precise flow regulation. This level of control is particularly important in processes where flow rates need to be closely monitored and maintained.

- Automation and Remote Operation: Pneumatic actuated ball valves can be easily integrated into control systems, allowing for automation and remote operation. They can be controlled and monitored remotely, which improves efficiency, reduces labor costs, and enables seamless integration with other devices and processes.

- Fast and Reliable Operation: Pneumatic actuated ball valves offer quick and reliable operation. The electric actuator provides rapid response times, allowing for fast opening and closing of the valve. This is crucial in applications where prompt flow control is required, such as emergency shutdown systems.

- Versatility and Flexibility: Pneumatic actuated ball valves are available in a wide range of sizes, materials, and configurations to suit various applications. They can handle different types of fluids, including corrosive or abrasive substances, and are suitable for high-pressure and high-temperature environments. This versatility makes them adaptable to a wide range of industries and processes.

- Energy Efficiency: Pneumatic actuated ball valves consume minimal energy during operation. They only require power when changing positions, and once the valve is in the desired position, it remains stable without consuming additional energy. This energy efficiency contributes to cost savings and reduces environmental impact.

- Safety and Reliability: pneumatic actuated ball valves offer enhanced safety features. They can be equipped with fail-safe mechanisms to automatically close or open in case of power failure or system emergencies. This ensures the safety of personnel, equipment, and the environment by preventing unintended flow or leakages.

- Long Service Life: pneumatic actuated ball valves are known for their durability and long service life. With proper maintenance, they can withstand harsh operating conditions and continue to perform reliably over an extended period. This durability reduces the need for frequent replacements and lowers maintenance costs.

Description

- Body Material: Carbon Steel, CF8M

- Ball Material: Stainless Steel

- Seat: PTFE, RTFE, PPL

- Nominal Diameter: DN15 to DN200

- Nominal Pressure: PN1.0MPa to PN6.4MPa

- End Connections: Flanged

- Input and Output Signal: DC 4-30mA, DC 0-10V, DC 1-5V

- Voltage: AC110-240V 380V 50/60Hz, DC 12V, DC 24V

- Power Supply: 24V AC, 24V DC, 110V AC, 230V AC

- Actuation Type: Pneumatic Actuated

Pneumatic 3 Piece Flanged Ball Valve

Pneumatic Actuated 3 Way Ball Valve

Pneumatic 3 Way Flanged Ball Valve

Pneumatic Actuated 2 Piece Ball Valve

Pneumatic Actuated 2 Piece Flanged Ball Valve

Pneumatic Actuated 3 Piece Ball Valve

Pneumatic Actuated Ball Valve

Pneumatic Actuated Ball Valve